Overview

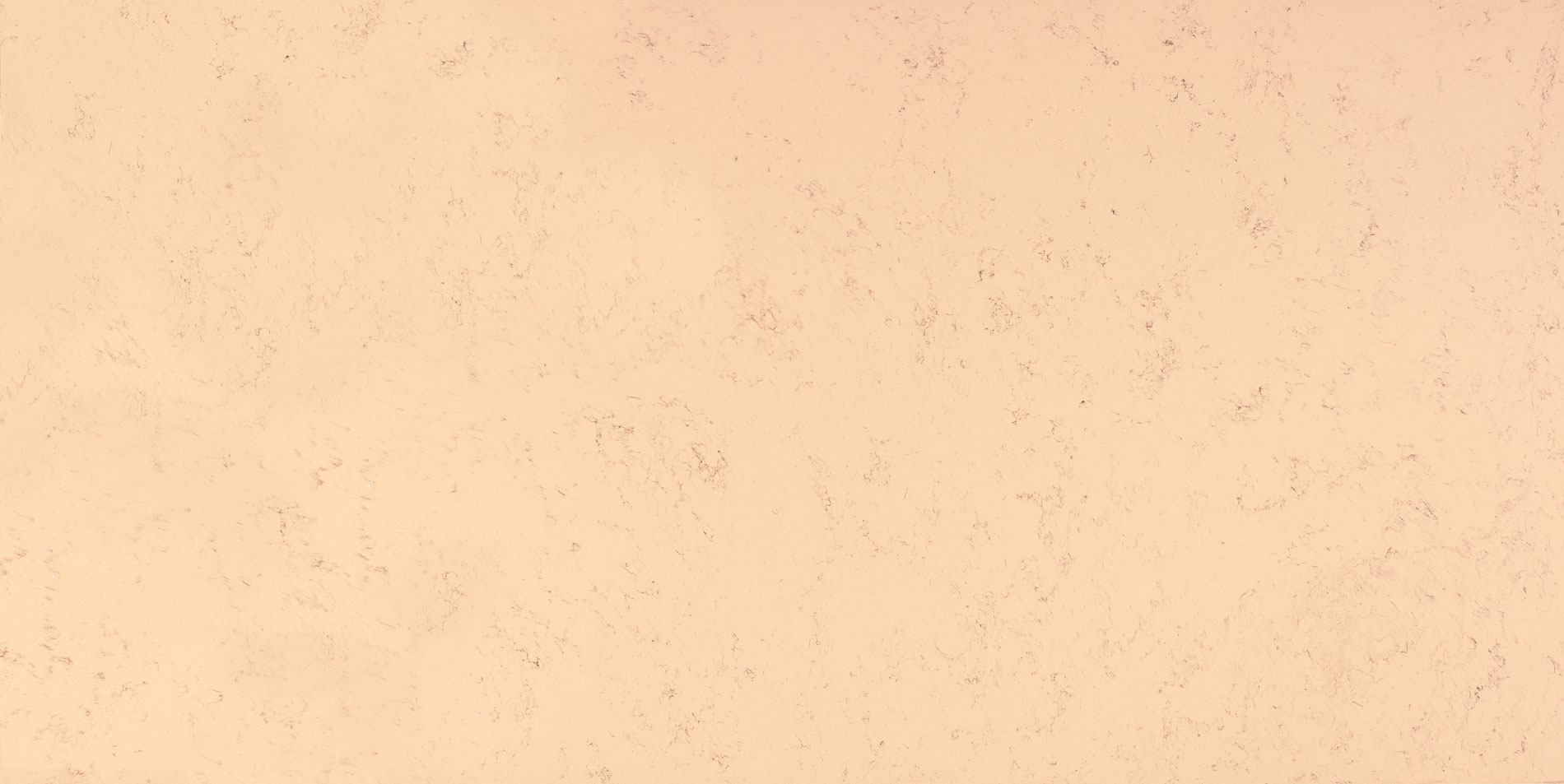

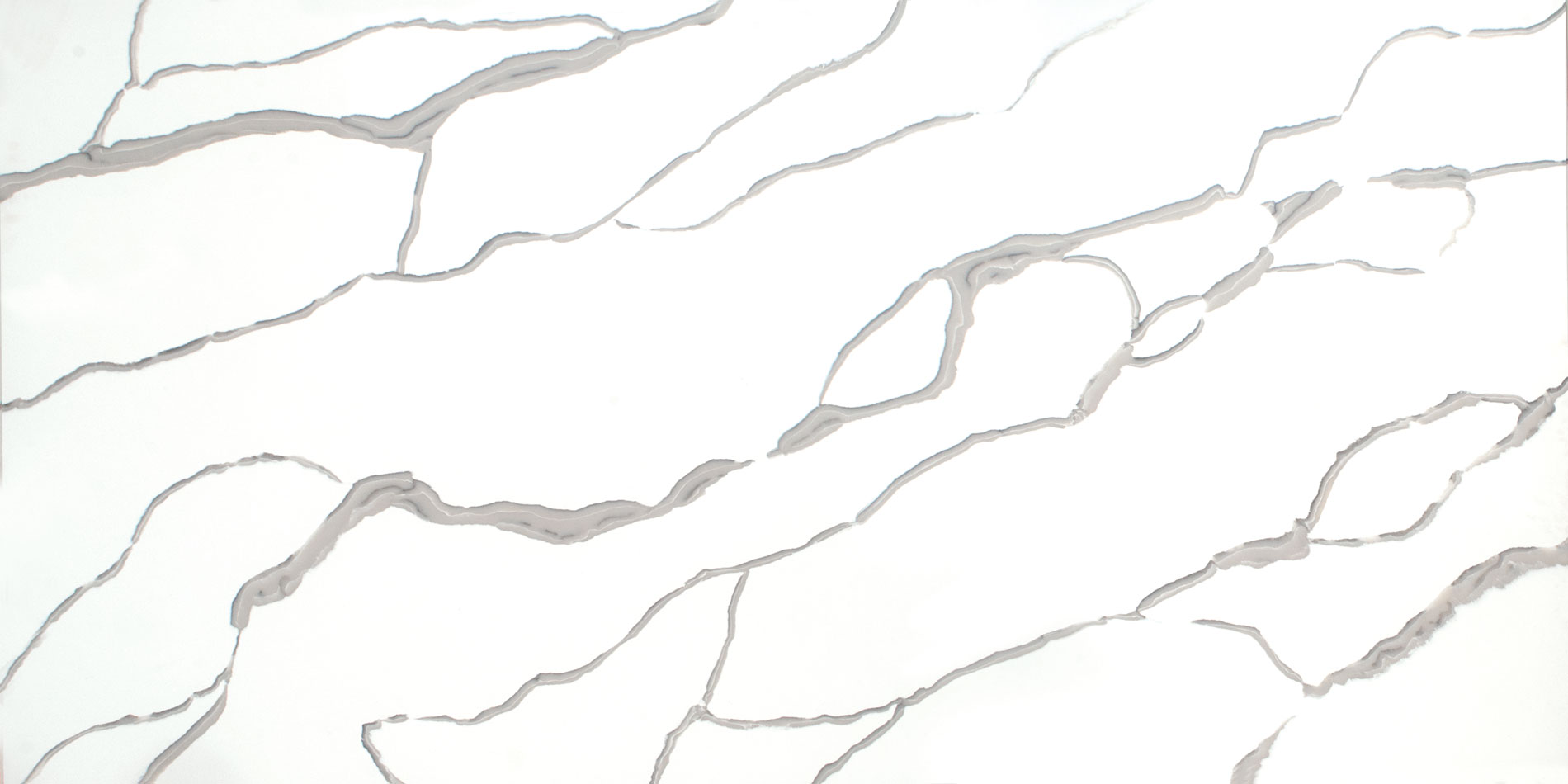

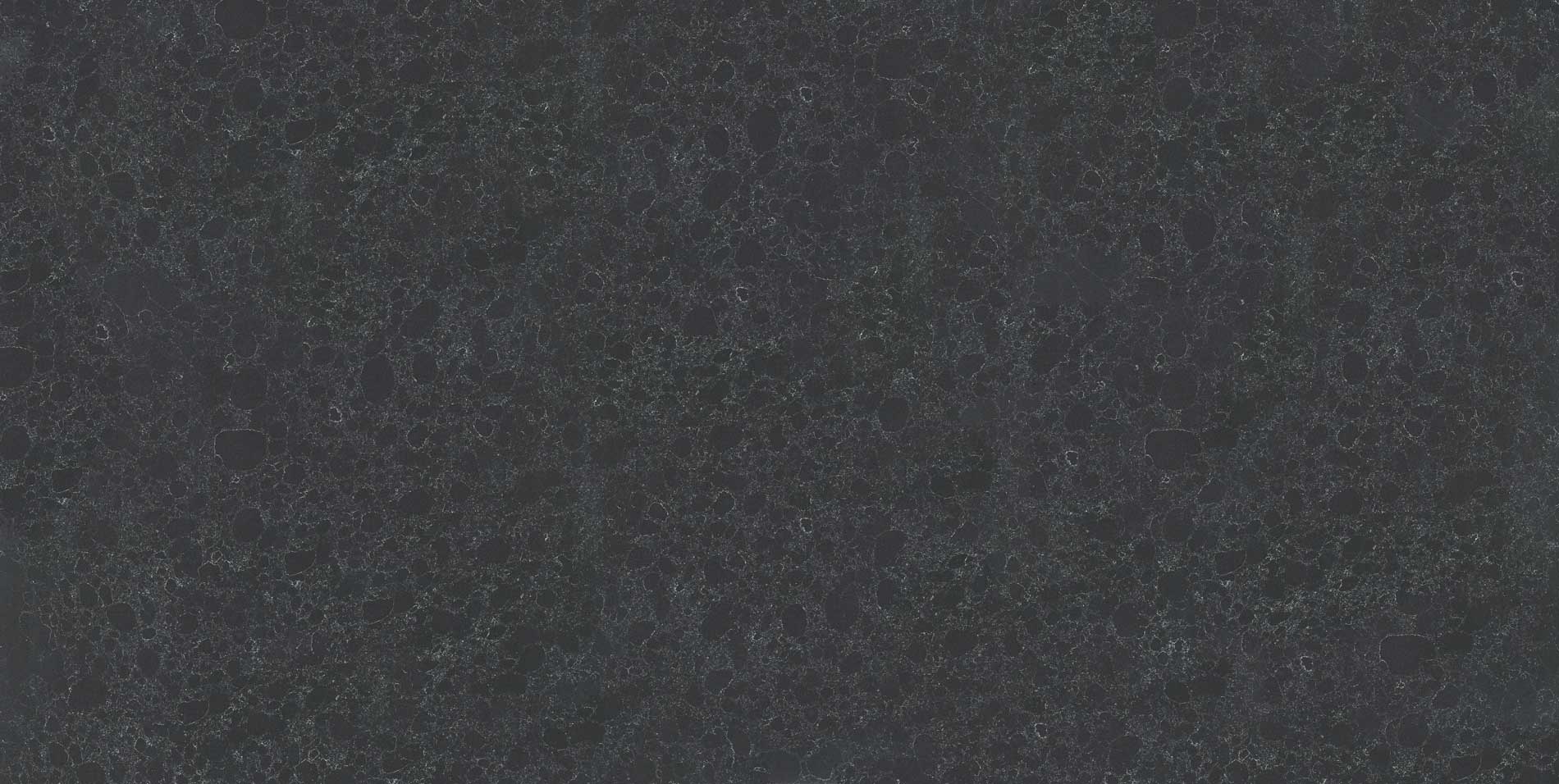

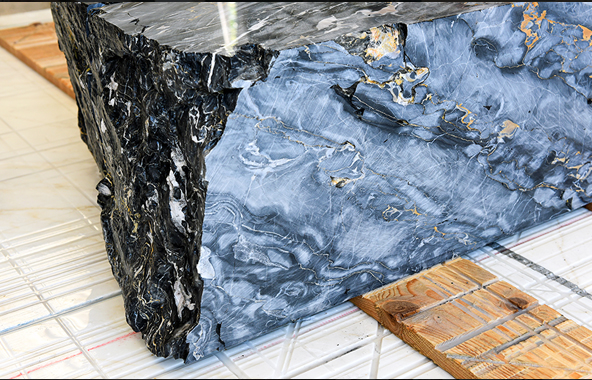

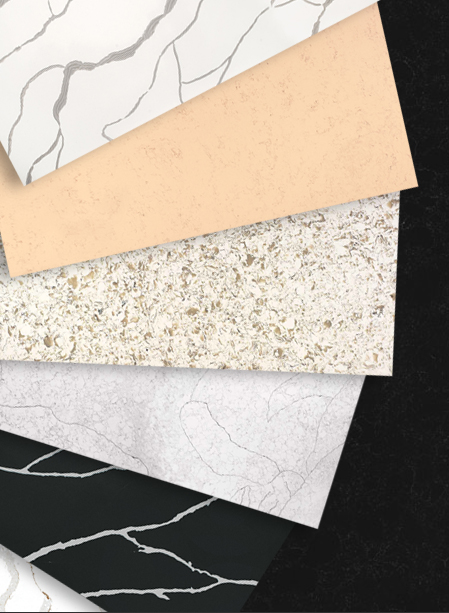

Composite or engineered quartz is a very solid material that resembles real granite in both look and utility. Engineered quartz is unaffected by stains, scratches, and cracks. It is also resistant to heat and cold. Engineered By blending quartz or granite aggregates with resins and pigments, man-made products like stone or quartz are created by quartz manufacturers in India, which are mostly generated from natural materials. The composition of engineered quartz slabs is typically 90% pulverised natural quartz and 10% polyresin. However, these percentages may vary slightly depending on the kind of quartz used.